HACCP in Malaysia: The Complete Guide for Food Safety & Certification

For food business owners, quality managers, and production leads across Malaysia, implementing a Hazard Analysis and Critical Control Point (HACCP) system has moved from a “competitive advantage” to a non-negotiable requirement for business survival and growth.

Whether you are a local producer supplying to major supermarkets, a manufacturer targeting export markets, or a food service operator aiming for the highest standards, HACCP certification is the universal language of food safety trust. It is mandated under Malaysia’s Food Act 1983 and is the definitive benchmark enforced by the Ministry of Health (MOH), recognized by exporters through SIRIM, and demanded by global supply chains.

Navigating the path to compliance, however, is complex. Between understanding the 7 principles of HACCP, aligning with the national standard MS 1480, building a competent team through the right HACCP training, and finally passing a rigorous certification audit, many businesses face costly delays and missteps.

This guide cuts through the complexity. As leading providers of HACCP training and consultancy in Malaysia, we have created this definitive resource to give you a clear, actionable roadmap. You will learn not just the theory, but the practical steps—from foundational HACCP awareness training for your staff to the final stages of securing your official certificate through our structured AKDeVeC™ consultancy framework.

Consider this your master blueprint for HACCP food safety success in Malaysia.

What is HACCP? A System for Proactive Food Safety

Hazard Analysis and Critical Control Point (HACCP) is not just another quality standard; it is a science-based, systematic, and preventive approach to food safety. Unlike traditional inspection methods that check finished products, a HACCP system is designed to identify, evaluate, and control potential biological, chemical, and physical hazards at every stage of the production process—from raw material receipt to the final product leaving the factory.

Think of it as building a series of safety nets into your process, rather than just inspecting for holes at the end. For a Malaysian food business, this means proactively preventing contamination in your sambal line, ensuring correct metal detection in your kuih packaging, and validating the cooking temperature of your ayam percik—before any unsafe product can reach a consumer.

“Note: The MS 1480 standard is dynamic. A significant revision, MS 1480:2025, has been published and will come into effect in January 2026. This update introduces important changes to hazard analysis, documentation, and compliance requirements. Businesses currently certified to the 2019 version should begin planning their transition. For a detailed breakdown of the key changes and a preparation roadmap, read our dedicated guide: MS 1480:2025 – Key Changes & What Malaysian Food Businesses Must Know.”

Why is HACCP Mandatory? Legal, Commercial & Safety Imperatives

Implementing HACCP is a critical business decision driven by three powerful forces:

Legal Compliance: Under Malaysia’s Food Act 1983 and regulations by the Ministry of Health (MOH), HACCP-based food safety systems are mandatory for specific food industry sectors, especially manufacturers and exporters. It is a fundamental component of the Food Safety Assurance Program (FSAP) or Program Jaminan Keselamatan Makanan (PJKM). Non-compliance isn’t just a risk; it’s a legal liability.

Commercial Necessity:

Export: A HACCP certificate from a recognized body like MOH is a prerequisite for exporting to countries like the EU, USA, Singapore, China and the Middle East.

Market Access: Major local retailers, hypermarkets, and multinational franchises (e.g., fast-food chains) require HACCP certification from their suppliers. If you are a restaurant planning to open your branch in Kuala Lumpur Convention Centre (KLCC), Alamanda Shopping Centre or Genting Highlands then HACCP certificate is a must.

Brand Protection: In an age of social media, a single food safety incident can destroy decades of brand equity. HACCP is your best defense.

Ethical Responsibility: Above all, it is your duty to consumers. Implementing HACCP demonstrates a commitment to producing food that is not only delicious but fundamentally safe.

HACCP & GMP: The Indispensable Partnership

A common point of confusion is the relationship between HACCP and Good Manufacturing Practices (GMP). They are not alternatives; they are interdependent layers of a complete food safety system.

GMP (and its related Prerequisite Programs – PRPs) form the foundational hygiene and operational conditions necessary for safe food production. This includes everything from facility sanitation and pest control to staff hygiene and equipment maintenance. Think of GMP as the “basic rules of the kitchen.”

HACCP is built on top of this solid GMP foundation. It is the targeted, risk-based system that addresses significant hazards that remain even under good GMP conditions. If GMP controls the general environment, HACCP controls the specific, critical points in the process.

You cannot have an effective HACCP system without robust GMPs in place. This is why many of our training programs, such as the GMP-HACCP Awareness Course, integrate both concepts from the start, ensuring your team understands this critical partnership from day one.

The 7 Core Principles of HACCP: Your System’s Blueprint

The entire HACCP system is constructed upon seven sequential principles. These are not abstract concepts but a practical, step-by-step methodology for building your food safety plan. Mastering these is the goal of effective HACCP training, and they form the non-negotiable foundation of the MS 1480 standard.

Principle 1: Conduct a Hazard Analysis

What it is: The foundational step where you list all potential biological (e.g., Salmonella, E. coli), chemical (e.g., allergens, cleaning residues), and physical (e.g., metal, glass, plastic) hazards that could occur at each process step.

Malaysian Example: In a cencaluk (fermented shrimp) operation, hazards include:

- Biological: Pathogen growth during fermentation.

- Chemical: Undeclared sulphites used as a preservative.

- Physical: Shell fragments from the raw shrimp.

Keyword Context: This is the “HA” in HACCP. A proper hazard analysis is the first major deliverable in any HACCP implementation training.

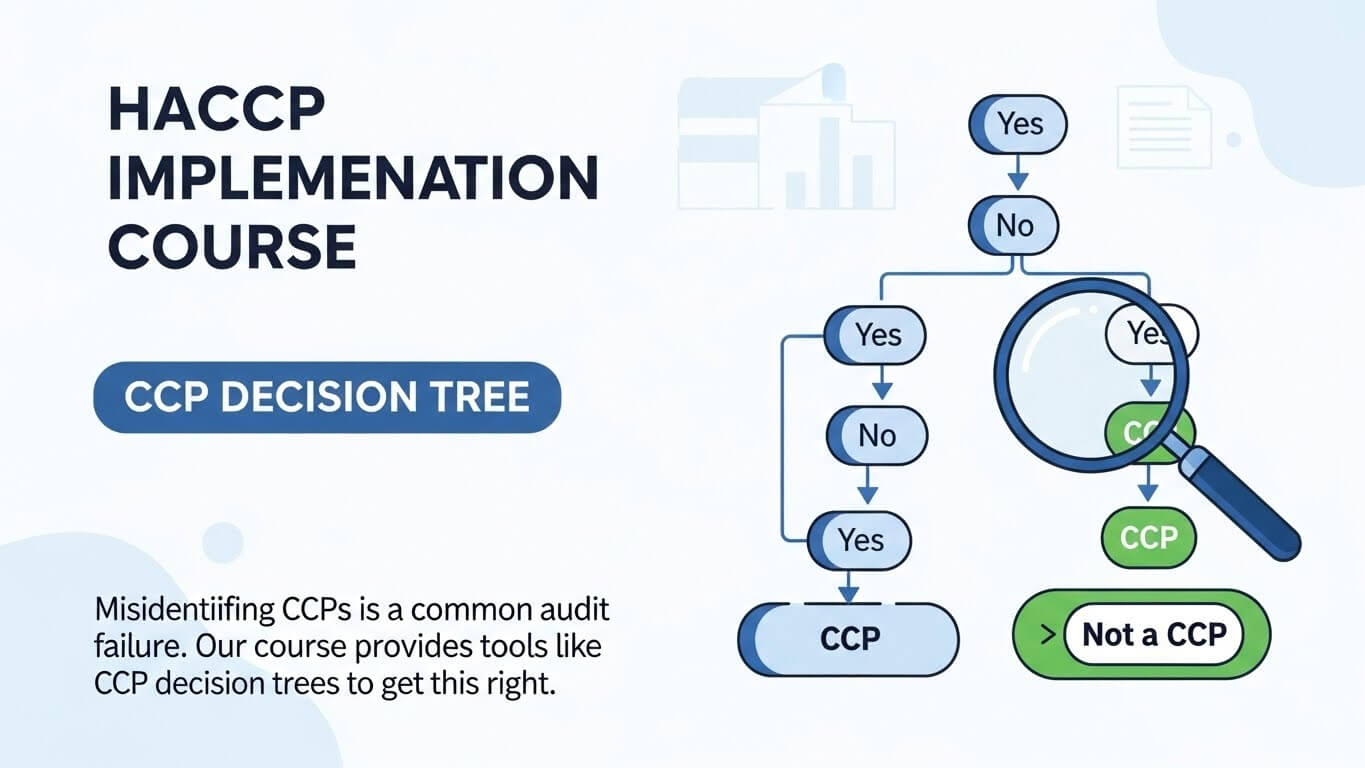

Principle 2: Determine the Critical Control Points (CCPs)

What it is: Identifying the specific points in your process where a hazard can be prevented, eliminated, or reduced to an acceptable level. Not every step is a CCP.

Malaysian Example: In a ready-to-drink teh tarik manufacturing line, the pasteurization step is a CCP for killing pathogens. The mixing step is likely not a CCP, as it doesn’t control a significant hazard.

Keyword Context: Misidentifying CCPs is a common audit failure. Our HACCP Implementation Course provides tools like CCP decision trees to get this right.

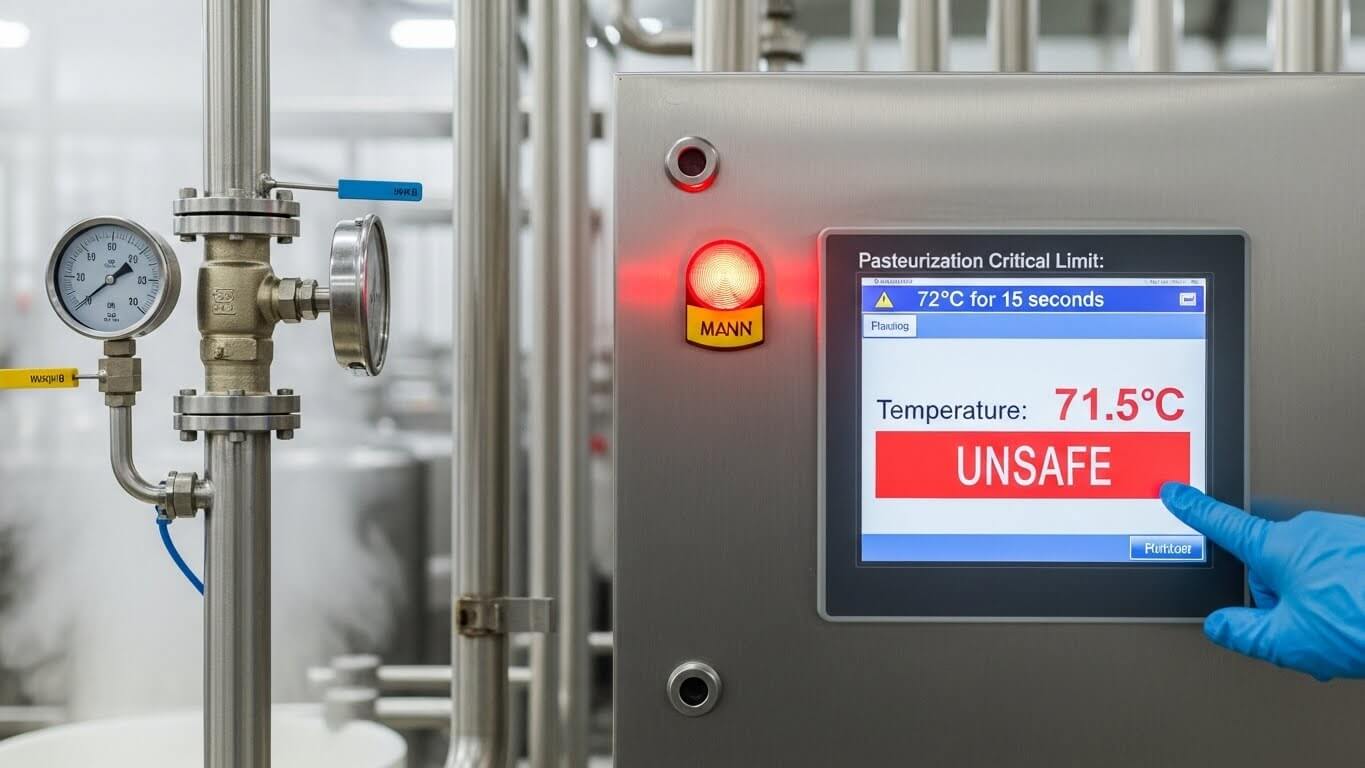

Principle 3: Establish Critical Limits for Each CCP

What it is: Setting the measurable, scientific boundaries for safety at each CCP. This is usually a minimum/maximum for parameters like temperature, time, pH, or moisture level.

Malaysian Example: For the pasteurization of susu lembu (milk), the critical limit might be heating to 72°C for at least 15 seconds. Any value below this is unsafe.

Keyword Context: These limits are the bedrock of your HACCP plan documentation and must be scientifically validated.

Principle 4: Establish Monitoring Procedures for CCPs

What it is: Defining how and how often you will check that the critical limits are being met. This creates the real-time record of your system’s performance.

Malaysian Example: At the milk pasteurization CCP, monitoring could involve: “Operator checks and records the pasteurizer temperature and flow rate every hour on the production log sheet.”

Keyword Context: Monitoring records are the first thing an auditor from MOH will examine. Staff must be trained on this in HACCP awareness programs.

Principle 5: Establish Corrective Actions

What it is: Pre-determining exactly what to do when monitoring shows a deviation from a critical limit. This is your “Plan B” to regain control and handle affected product.

Malaysian Example: If the pasteurizer temperature drops below 72°C, corrective actions may include: 1) Divert the product to a holding tank for re-pasteurization, 2) Identify and repair the equipment fault, 3) Quarantine and assess all product produced since the last good check.

Keyword Context: A lack of documented, effective corrective actions is a major non-conformity. This is covered in-depth in internal audit training.

Principle 6: Establish Verification Procedures

What it is: The activities that confirm your HACCP system is working effectively over time. This is the “check” on your “plan” and “do.”

Malaysian Examples:

Calibrating thermometers and scales weekly.

Quarterly internal audits of the entire HACCP system.

Annual review of the HACCP plan by top management.

Sending finished product for microbial testing.

Keyword Context: Verification is the essence of HACCP internal audit training. Your team learns to conduct these checks systematically.

Principle 7: Establish Documentation & Record-Keeping

What it is: Maintaining all procedures, plans, and records that demonstrate your system is active and effective. “If it isn’t written down, it didn’t happen” in the eyes of an auditor.

Required Documents (MS 1480): HACCP Plan, Hazard Analysis worksheets, CCP monitoring records, corrective action reports, verification records (audits, calibration), and prerequisite program (GMP) manuals.

Keyword Context: Documentation is the most tangible output of a HACCP consultancy project and the primary evidence for certification.

Bringing the Principles Together: A Cohesive System

These principles are a cycle, not a one-time list. Principle 7 (Documentation) feeds back into Principle 1 (Hazard Analysis) during annual reviews. A true understanding of how they interlock is what separates a paper system from a living, breathing culture of food safety—a culture built through comprehensive HACCP training and sustained by diligent internal verification.

MS 1480:2019 – Understanding Malaysia’s HACCP Standard

For any food business operating in or exporting from Malaysia, the national standard MS 1480:2019 – “Food safety according to the Hazard Analysis and Critical Control Point (HACCP) system” is the definitive rulebook. It is not merely a guideline; it is the specific technical specification against which the Ministry of Health (MOH), and other certification bodies will assess your HACCP system for compliance.

Think of MS 1480 as the “Malaysian translation” of global HACCP principles, incorporating local regulatory requirements and best practices. Compliance with MS 1480 is synonymous with building a HACCP system that will pass a Malaysian certification audit.

The Structure of MS 1480: How it Organizes the HACCP Journey

MS 1480 is structured to logically guide an organization from foundational concepts to system operation:

Scope & Normative References: Defines what the standard covers.

Terms & Definitions: Establishes a common language for HACCP food safety.

Prerequisite Programs (PRPs): Details the mandatory foundational requirements, which are based on Good Manufacturing Practices as specified in MS 1514:2022. This directly addresses the

haccp and gmprelationship, with GMP being the critical foundation.The 12 Steps & 7 Principles of HACCP: This is the core of the standard, detailing the systematic application of the principles we outlined in Part 2, from assembling the HACCP team to establishing verification procedures.

Implementation & Maintenance: Outlines requirements for keeping the system current and effective, linking directly to ongoing training and internal audits.

The Critical Link: MS 1480 (HACCP) and MS 1514:2022 (GMP)

A fully compliant HACCP system under MS 1480:2019 requires the effective implementation of Good Manufacturing Practices as defined in MS 1514:2022. You cannot have one without the other.

MS 1514:2022 (GMP) sets the requirements for the basic hygienic and operational conditions of your facility, staff, and processes.

MS 1480:2019 (HACCP) is the risk-based management system built upon that stable GMP foundation to control specific, significant hazards.

This is why our foundational GMP-HACCP Awareness Course covers both standards integrally, ensuring your team understands this non-negotiable partnership from the start.

Who Needs to Comply with MS 1480?

Compliance is critical for:

Food Manufacturers & Processors: From large-scale integrated facilities to small & medium enterprises (SMEs) producing anything from baked goods to frozen meals.

Export-Oriented Businesses: A prerequisite for obtaining the HACCP certificate needed for export clearance.

Businesses in Regulated Sectors: Specifically those under the purview of MOH’s Food Safety and Quality Division.

Any Business Seeking Certification: SIRIM and other certification bodies audit explicitly against the clauses of MS 1480 and the foundational requirements of MS 1514.

Navigating MS 1480 & MS 1514 Compliance: The Role of Expert Guidance

Interpreting these standards and translating them into your specific operation is where many businesses struggle. A generic understanding is not enough—you need Malaysian standard-specific expertise.

This is where structured HACCP and GMP training aligned with MS 1480 & MS 1514 and expert consultancy become invaluable. For instance:

Our HACCP Implementation Course teaches how to develop documentation that meets MS 1480’s specific clauses, on top of a GMP base.

Our HACCP Internal Auditor Training focuses on auditing against MS 1480’s requirements and the effectiveness of underlying GMPs.

Our AKDeVeC™ Consultancy Framework ensures every phase of your project is meticulously aligned with MS 1480:2019 and MS 1514:2022, eliminating guesswork and ensuring audit readiness.

Understanding these standards is the first step; implementing them effectively is the next. The following sections of this guide will map out the exact training pathway and certification roadmap to achieve this.

Building Your HACCP Team: The First Step to Success

A HACCP system is only as strong as the people who operate it. Before drafting a single document, you must assemble and empower a dedicated HACCP Team. This cross-functional group typically includes representatives from Production, Quality Assurance, Engineering, and Senior Management.

Their first and most crucial task? To gain the collective knowledge required to build, implement, and maintain the system. This is where structured HACCP training moves from an option to an imperative.

The Essential HACCP Training Pathway: From Awareness to Expertise

There is no “one-size-fits-all” HACCP course. Competence is built in layers, matching the complexity of the system itself. At Al-Barakah, we structure this journey into a clear, three-tiered pathway designed to equip every level of your organisation with the precise skills they need. Below listed HACCP level1,2 &3 trainings.

Level 1: HACCP & GMP Awareness – Building the Foundation

Target Audience: Every employee involved in food handling, production, storage, and distribution. This includes operators, cleaners, warehouse staff, and new hires.

Objective: To create a universal baseline of food safety culture. Staff must understand why hygiene rules exist, what GMP is, and their personal role in preventing contamination.

What It Covers: Introduction to HACCP food safety concepts, personal hygiene, cross-contamination, allergen awareness, and basic MS 1514:2022 GMP requirements.

HACCP Level 2: Implementation & Development – For the Core Team

Target Audience: The HACCP Team members, Quality Managers, and Technical leads who will be responsible for developing and documenting the system.

Objective: To translate the 7 principles of HACCP into your specific HACCP Plan. This is the hands-on, practical skillset needed for MS 1480:2019 compliance.

What It Covers: Conducting a live Hazard Analysis, using decision trees to identify Critical Control Points (CCPs), establishing critical limits, and designing monitoring and corrective action procedures. The output is the draft of your core HACCP documentation.

Level 3: Internal Auditor Training – Mastering System Verification

Target Audience: Designated internal auditors, QA supervisors, and HACCP team leaders responsible for checking the system’s effectiveness.

Objective: To develop the skills to plan, conduct, report, and follow up on internal audits. This is not just about finding faults, but verifying that the entire HACCP system is working as designed and is ready for the external certification audit.

What It Covers: Audit principles against MS 1480, audit planning and checklist development, interview techniques, evidence gathering, writing non-conformity reports, and conducting audit follow-up.

Choosing the Right HACCP Training Course in Malaysia

With many providers offering haccp training malaysia, your choice should be guided by:

| Course | Who It’s For | Key Skills Developed | Duration |

|---|---|---|---|

| Level 1: HACCP & GMP Awareness Training | All production staff, new hires | Foundational food safety principles, GMP requirements, personal hygiene. | 1 Day |

| Level 2: HACCP Implementation Course | HACCP Team Leaders, QA/QC Staff | How to conduct hazard analysis, develop a HACCP Plan, write SOPs. | 2-3 Days |

| Level 3: Practical HACCP Internal Auditor Training | Internal auditors, QA Managers | Planning, conducting, and reporting internal audits against MS 1480. | 2 Days |

Alignment with Malaysian Standards: Does the course content explicitly reference MS 1480:2019 and MS 1514:2022?

Practical, Not Just Theoretical: Does it offer hands-on workshops (e.g., creating a hazard analysis for a local product) or is it only lecture-based?

Structured Pathway: Does the provider offer a logical progression of courses (like the Levels 1-3 above) to support your team’s long-term development?

Expertise of Trainer: Are the facilitators seasoned professionals with direct experience in HACCP certification audits in Malaysia?

Investing in this structured HACCP training pathway does more than check a box. It builds the internal competence that is the single greatest determinant of certification success. It transforms your HACCP system from a set of documents into a lived practice.

The next part of this guide will show you how this trained competence integrates into the final journey: securing your official certificate.

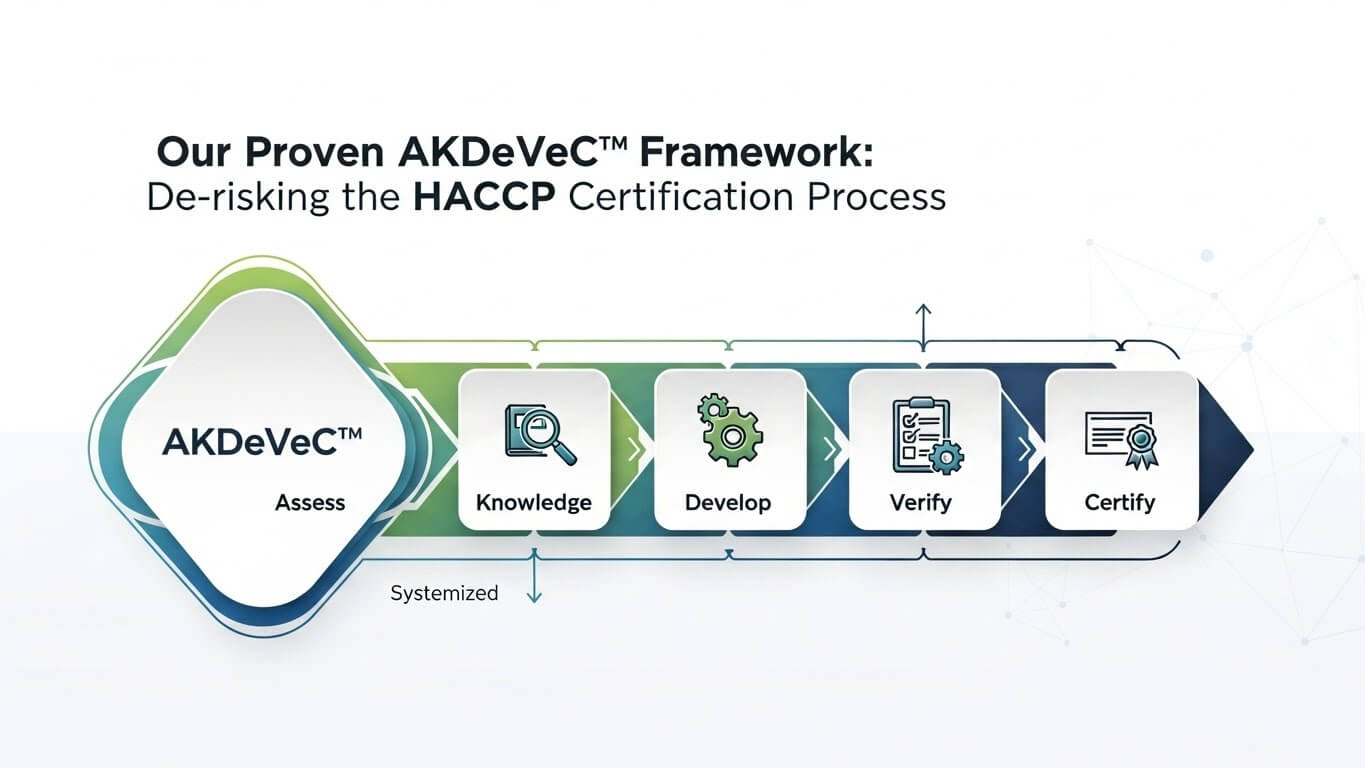

How to Get HACCP Certified in Malaysia: The AKDeVeC™ Roadmap

Understanding HACCP is one thing; successfully navigating the formal certification process with bodies like MOH, SGS, or Sirim is another. This is where many competent teams falter, facing costly delays, audit non-conformities, and frustration.

At Al-Barakah, we have systemized this complex journey into our proven AKDeVeC™ Framework—a proprietary, five-phase methodology that de-risks the entire process. It seamlessly integrates the team training from Part 4 with expert-led project management, ensuring you build competence and achieve certification in one streamlined, predictable engagement.

Phase A – Analysis: The Diagnostic Blueprint

The Goal: To establish an undeniable fact base and a clear roadmap.

The Process: We conduct a comprehensive Gap Analysis of your existing operations, documentation, and facilities against the specific requirements of MS 1480:2019 and your target certification body (e.g., MOH, SIRIM, SGS ).

The Outcome: A detailed, transparent project report outlining the precise scope of work, a realistic timeline (typically 6-9 months), and a fixed-fee proposal. No surprises.

Phase K – Knowledge: Building Institutional Competence

The Goal: To transform your staff from attendees to capable implementers.

The Process: This is where our structured HACCP Training Pathway is integrated into the consultancy project. We don’t just build a system for you; we build knowledge within you through:

- HACCP Level 1 (Awareness) for all staff.

- HACCP Level 2 (Implementation) for your HACCP team.

- HACCP Level 3 (Internal Audit) for your auditors.

The Outcome: A workforce that understands the why and the how. This phase directly addresses the root cause of most failures: a lack of skilled personnel. It ensures your team can own and operate the system long after we’re gone. Don’t worry, this training is fully HRDCorp Claimable!

Phase De – Development: Creating Your Compliant HACCP System

The Goal: To translate knowledge and analysis into a certified-ready documentation suite.

The Process: Our lead consultants work alongside your now-trained HACCP team to develop your complete food safety management system. This includes the HACCP Plan, all Prerequisite Program (PRP) manuals aligned with MS 1514:2022 (GMP), SOPs, and the full record-keeping framework required by MS 1480.

The Outcome: A fully documented, customized, and compliant HACCP system that is both audit-ready and practical for your daily operations.

Phase Ve – Verification: Stress-Testing Before the Real Audit

The Goal: To validate the system’s effectiveness and your team’s readiness.

The Process: Your newly trained internal auditors, supported by our experts, conduct the mandatory internal audits. We then perform a rigorous mock certification audit, simulating the exact process of SIRIM or MOH auditors, identifying and closing any final gaps.

The Outcome: A verified, robust system and a confident team. You enter the official audit with zero unknowns, having already passed a tougher rehearsal.

Phase C – Certification: Securing Your Official HACCP Certificate

The Goal: The successful grant of your HACCP certificate.

The Process: We act as your technical liaison and on-site support team. We manage all communication with the certification body, submit documentation, and provide expert guidance during the final certification audit to ensure a smooth, successful outcome.

The Outcome: Your official HACCP certificate from your chosen body (MOH, SIRIM etc.), granting you market access, regulatory compliance, and consumer trust.

Why the AKDeVeC™ Framework is Your Guarantee Against Failure

Choosing the AKDeVeC™ Framework is not just hiring a consultant; it’s partnering for guaranteed success. Here’s why it works:

Solves the Core Problem: It uniquely integrates mandatory training (Phase K) into the project, ensuring your team’s competence—the single biggest factor in long-term success—is not an afterthought.

De-risks Investment: The phased approach, with a fixed scope after the Analysis phase, provides complete budget and timeline predictability.

Builds Lasting Internal Expertise: You don’t just get a certificate; you build a self-sufficient team that can maintain, audit, and improve the system, ensuring ongoing compliance and a strong return on investment.

Proven Track Record: This structured methodology is the reason our clients achieve certification efficiently, often on their first audit attempt.

Use it!

Your journey from understanding HACCP to holding the certificate now has a clear, branded, and proven path.

Beyond Certification: How to Maintain and Improve Your HACCP System

Securing your HACCP certificate is a major achievement, but it is a milestone, not the finish line. The true value of your investment is realized through the ongoing effectiveness of your food safety system. A static system will quickly become non-compliant. Maintenance is an active, continuous process.

The Cycle of Maintenance: Plan-Do-Check-Act (PDCA)

Your HACCP system should operate on a continuous improvement cycle:

Plan: Review and update your HACCP plan annually or when processes change.

Do: Ensure daily activities follow documented SOPs and PRPs.

Check: Conduct regular internal audits and management reviews.

Act: Implement corrective actions for non-conformities and seek opportunities for improvement.

Key Maintenance Activities

Scheduled Internal Audits: Your trained internal auditors should conduct audits at planned intervals (e.g., quarterly) against MS 1480 to verify compliance.

Annual Management Review: Top management must formally review the system’s suitability, adequacy, and effectiveness, using data from audits, incidents, and customer feedback.

Ongoing Training & Awareness: New staff must undergo Level 1 Awareness training. Existing staff need refreshers. Consider advanced food safety training like Food Allergen Management to address evolving risks.

Document Control: All HACCP documents must be kept current. Any change to a process, ingredient, or equipment necessitates a review of the hazard analysis and relevant procedures.

Dealing with Non-Conformities: Every deviation, customer complaint, or audit finding must be logged, investigated, and resolved with effective corrective actions to prevent recurrence.

The Role of Continuous Training in System Integrity

Maintenance is fundamentally a people-driven activity. A lapse in staff competence can break the entire system. Investing in refresher courses and advanced food safety training ensures your team’s knowledge remains sharp and adapts to new challenges. This transforms your HACCP system from a compliance cost into a dynamic driver of operational excellence and brand protection.

Conclusion & Your Next Step

You have now navigated the complete landscape of HACCP in Malaysia—from its fundamental principles and local standards to the precise pathway for building competence and achieving certification.

The journey is clear:

Understand the requirements (MS 1480:2019 & MS 1514:2022).

Train your team at every level (Awareness > Implementation > Internal Audit).

Implement & Verify your system with expert support.

Achieve & Maintain your official certification.

Where is your business on this path?

If you need to build your team’s competence, explore our structured HACCP Training Pathway.

If you are ready to secure your HACCP certificate, let’s discuss a clear, managed project using our AKDeVeC™ Framework. Contact our team.

[FAQ’s] HACCP in Malaysia: Your Top Questions Answered

Q1: What is the difference between HACCP training and HACCP certification?

A: HACCP training provides the knowledge and skills to your team (e.g., awareness, implementation, auditing). A HACCP certificate is the official document issued by an accredited body (like SIRIM or MOH) after a successful audit of your implemented system. Training builds competence; certification proves compliance.

Q2: How long does it take to get HACCP certified in Malaysia?

A: For a business starting from scratch, a typical timeline using a structured consultancy like our AKDeVeC™ Framework is 6 to 9 months. This includes the time for team training, system development, internal verification, and the official certification audit. The duration depends on your starting point and chosen certification body.

Q3: Can we implement HACCP and get certified without a consultant?

A: For first time application it is technically possible but highly challenging and risky. The most common pitfalls—incorrect hazard analysis, poor documentation, and unprepared teams—often lead to audit failures, wasting significant time and money. A consultant provides expert guidance, ensures alignment with MS 1480, and de-risks the entire investment, significantly increasing your chance of first-time success.

Q4: What is the validity period of a HACCP certificate?

A: A HACCP certificate is typically valid for three years. During this period, the certification body will conduct annual surveillance audits to ensure ongoing compliance.

Q5: How much does HACCP certification cost in Malaysia?

A: Costs vary significantly based on company size, process complexity, and chosen certification body. Investment includes training costs for your team, potential consultancy fees, and the certification body’s fees for audit and certificate issuance. The most cost-effective approach is a bundled solution that integrates training and consultancy to avoid costly re-audits.