A Halal product that survives the journey faces its next critical test: storage. Unlike transportation’s moving risks, warehousing presents a static, accumulating threat—where cross-contamination can occur slowly, invisibly, and irreversibly if controls fail.

Where transportation is about custody during movement, warehousing under MS2400:2019 is about custody through time and space. It transforms a warehouse from a passive holding area into an active, controlled ecosystem designed to preserve Halal integrity. A single error in zoning, a pest breach, or improper handling during storage can compromise an entire batch, negating all prior compliance efforts.

The Halal integrity of a product arriving at your dock is only as good as the controls during its transportation and shipping. Before implementing warehouse controls, ensure you understand the risks and compliance requirements for Halal transportation.

This guide provides the blueprint. We translate MS2400-2’s requirements into actionable strategies for warehouse design, daily operations, and staff protocols, ensuring your storage facility acts as a fortress, not a fault line, in your Halal supply chain.

The Foundational Principle: Zoning as the First Line of Defense

The core of MS2400-2 compliance is physical and procedural segregation. Your warehouse must be logically mapped to prevent any contact between Halal and non-Halal items.

The Three-Zone Model (A practical interpretation of MS2400-2):

Dedicated Halal Zone: Exclusively for certified Halal products. Ideally, this is a physically separate room or a clearly demarcated area with restricted access. This is your high-integrity core.

General Storage Zone: For non-Halal, non-hazardous materials (e.g., packaging, stationery, equipment). There must be a clear and fixed boundary separating this from the Halal zone.

Quarantine & Non-Halal Zone: A secured area for receiving non-Halal goods, holding suspect/damaged items, or storing definitively non-Halal products. This zone must have separate material handling equipment (MHE) and access protocols.

This logical segregation is a core principle also emphasized in broader quality management systems (ISO 9001) that form the basis of many operational standards.

Critical Operational Control Points in Halal Warehousing

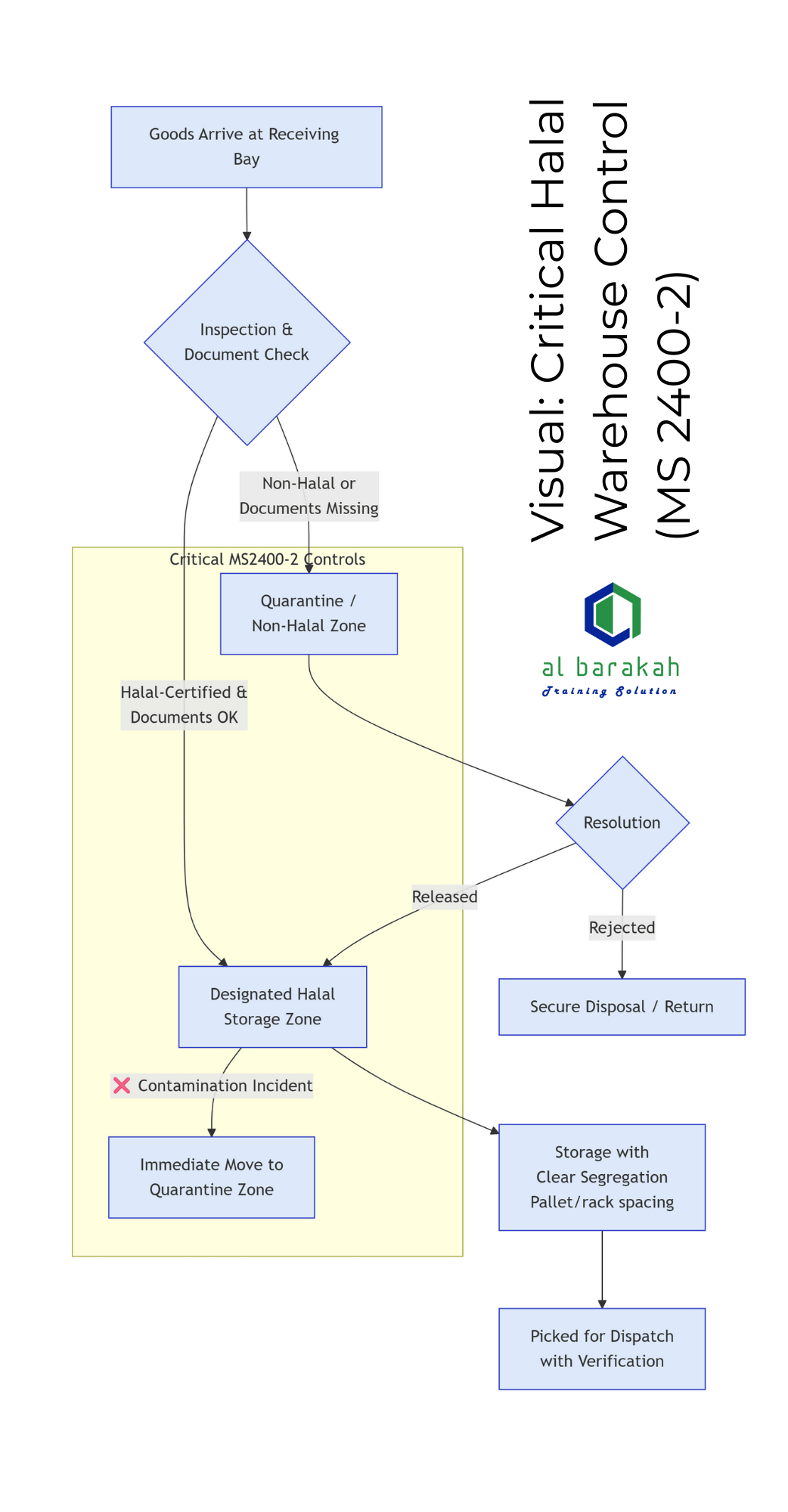

Control Point 1: Receiving & Verification

The Risk: Accepting non-Halal or contaminated goods into the Halal zone.

The MS2400-2 Requirement: All inbound goods must be verified against documentation (Halal certificate, transport documents) before being accepted and moved to storage.

Implementation Action: Establish a “Hold Point” at receiving. No goods move to storage until a checklist is completed and signed by authorized personnel.

Control Point 2: Storage Segregation & Traceability

The Risk: Within the Halal zone, different product types (e.g., food, cosmetics, pharmaceuticals) or products from different suppliers could cross-contaminate.

The MS2400-2 Requirement: Storage must be organized to prevent mixing and allow for full traceability (lot tracking).

Implementation Action: Implement “Slotting” rules: defined rack/pallet locations for product categories. Use clear labeling and maintain a warehouse management system (WMS) or logbook to track location and movement.

Control Point 3: Pest Control & Environmental Management

The Risk: Pests (rodents, insects) are carriers of najs and can cause widespread contamination.

The MS2400-2 Requirement: The warehouse must be designed and maintained to prevent pest access and harborage.

Implementation Action: Go beyond basic spraying. Implement an Integrated Pest Management (IPM) program: seal entry points, maintain cleanliness, use monitored bait stations, and conduct regular audits.

An effective program goes beyond reaction and should be proactive, similar to the preventive approach found in comprehensive food safety management systems.

Control Point 4: Handling of Non-Conforming Stock

The Risk: A damaged, leaking, or suspect package can contaminate surrounding stock.

The MS2400-2 Requirement: Procedures must exist for immediate isolation, evaluation by the Internal Halal Committee, and proper disposal of contaminated stock. Members of the Internal Halal Committee who will make these critical disposition decisions require advanced knowledge beyond basic awareness.

Implementation Action: Place “Quarantine Cages” or marked areas in both Halal and receiving zones. Train all staff on the “Stop, Isolate, Report” procedure for any damaged goods.

Control Point 5: Personnel & Equipment Flow

The Risk: Staff or forklifts moving between zones can act as contamination vectors.

The MS2400-2 Requirement: Movement of personnel and MHE should be controlled to protect Halal integrity.

Implementation Action: Create one-way traffic flows where possible. Consider color-coded uniforms or tooling for staff working in dedicated zones. Dedicate MHE to the Halal zone, or mandate strict cleaning before entry.

The Sertu Procedure in a Warehouse Context

While similar to transport, sertu in warehousing often involves fixed infrastructure (flooring, racks, drainage). MS2400-2 mandates that the process must be supervised by a Halal competent authority or trained Muslim personnel. Your procedures must detail:

Containment: Isolating the affected area.

Cleaning: Physical removal of the contaminant.

Sertu Execution: The 7-time washing with water and soil mixture.

Verification & Documentation: Sign-off before the area is returned to use.

Building Your Halal Compliant Warehouse: From Plan to Practice

Map Your Current State: Draw a physical layout of your warehouse and mark all material flows. Identify current mixing points.

Design Your Ideal State: Using the Three-Zone Model, redesign the layout on paper. Plan for physical barriers (walls, fences), signage, and dedicated equipment.

Develop the Supporting System: Write SOPs for receiving, storage, pest control, non-conformance, and sertu. Create all necessary checklists and logs.

Train Competently: Basic Halal principles even though is compulsory but it is not enough. Staff need practical, scenario-based training. Our Halal Assurance in Logistics & Supply Chain Training provides this essential competency, covering warehouse-specific simulations and problem-solving.

Audit Relentlessly: Conduct weekly visual checks and monthly formal internal audits against your own procedures and MS2400-2. These internal checks are critical preparation for the formal evaluation during an external halal certification audit.

The Warehouse as a Strategic Asset

A MS2400-2 compliant warehouse is not an expense; it’s a revenue-protecting, brand-shielding strategic asset. It gives Halal brand owners the confidence to store with you and gives your sales team a powerful competitive edge in the growing Halal logistics market.

Your storage facility should be the strongest link in the chain. Fortify it with knowledge and precise practice.

Ready to transform your storage operations?

- Equip your team with our specialized Halal Logistics & Supply Chain Training

- Start with awareness training to all staff

- Continue with Halal implementation for warehousing and supply chain

- Complete team competency with Internal Halal Audit & Verification Training.

Contact us for a Halal Warehouse Gap Analysis Consultation