Introduction of ISO 9001 in Malaysia

In today’s competitive global marketplace, Malaysian businesses face a dual challenge: meeting international standards while carving out a distinct reputation for reliability and excellence. For organizations from Kuala Lumpur’s financial hubs to Penang’s manufacturing centres and beyond, a strategic commitment to quality is no longer optional – For businesses in the food sector, this quality foundation often works in tandem with specific food safety standards.

Organizations pursuing integrated management systems often find that the process-oriented framework of ISO 9001 provides an excellent base for implementing standards like FSSC 22000 for food safety or HACCP principles.

The Strategic Value of ISO 9001

This is where ISO 9001, the internationally recognized benchmark for Quality Management Systems (QMS), transitions from a technical specification to a powerful strategic tool. Adopting ISO 9001 in Malaysia is not merely about obtaining a certificate for the office wall. It represents a deliberate choice to embed a culture of continuous improvement, operational resilience, and customer-centricity into the very fabric of an organization.

For Malaysian enterprises, the value of ISO 9001 certification extends far beyond compliance. It is a key that unlocks:

Enhanced Market Credibility: In both domestic tenders and international export markets, the ISO 9001 badge signals a proven, audited commitment to quality, often serving as a mandatory prerequisite for lucrative contracts.

Operational Efficiency & Cost Reduction: By streamlining processes, reducing errors and waste, and fostering a preventive mindset, the standard drives significant bottom-line improvements.

Strengthened Customer Trust: A systematic approach to meeting customer requirements and enhancing satisfaction leads to higher retention rates and a stronger brand reputation.

A Framework for Resilience: The ISO 9001:2015 revision, with its emphasis on risk-based thinking, provides organisations with a structured way to anticipate and navigate challenges, from supply chain disruptions to evolving market demands.

This guide serves as your definitive resource on the ISO 9001 certification process in Malaysia. We will move beyond the basics to provide a comprehensive understanding of the standard’s principles, its specific application within the Malaysian regulatory and business context, and the practical pathway from initial exploration to successful implementation and maintenance. Whether you are a senior executive evaluating its strategic impact, a quality manager tasked with its rollout, or simply seeking to understand its relevance, the following sections will equip you with the knowledge to make informed decisions for your organization’s future.

The Core Principles of a Modern ISO 9001:2015 QMS

To move beyond seeing ISO 9001 as a mere set of requirements, it is essential to understand the foundational philosophy that drives it. The ISO 9001:2015 standard is built upon seven Quality Management Principles (QMPs). These are not just abstract ideals; they are a strategic framework designed to guide organisational behaviour and decision-making towards sustained success.

For Malaysian businesses, embracing these principles means shifting from a reactive, inspection-based approach to quality, to a proactive, integrated, and holistic system of management.

The following table outlines each principle, its core rationale, and its practical implication for a Malaysian organisation:

| Quality Management Principle | What It Means | Practical Implication for Your Organisation |

|---|---|---|

| 1. Customer Focus | The primary focus of quality management is to meet customer requirements and strive to exceed customer expectations. | Moves beyond basic satisfaction to understanding latent needs, ensuring your services/products solve real problems for the Malaysian market and build loyalty. |

| 2. Leadership | Leaders at all levels establish unity of purpose and direction and create conditions in which people are engaged in achieving the organisation’s quality objectives. | Requires management to actively champion the QMS, integrate it with business strategy, and foster a culture where quality is everyone’s responsibility. |

| 3. Engagement of People | Competent, empowered, and engaged people at all levels throughout the organisation are essential to enhancing its capability to create and deliver value. | Empowers employees from the factory floor to the front desk to identify improvements, leading to higher morale and operational innovation. |

| 4. Process Approach | Consistent and predictable results are achieved more effectively and efficiently when activities are understood and managed as interrelated processes that function as a coherent system. | Encourages mapping and optimizing the flow of work across departments (e.g., from procurement to delivery), breaking down silos and reducing inefficiency. |

| 5. Improvement | Successful organisations have an ongoing focus on improvement. | Establishes a cycle of incremental refinement and breakthrough change, making the organisation more resilient to shifts in the Malaysian economy and competitive landscape. |

| 6. Evidence-Based Decision Making | Decisions based on the analysis and evaluation of data and information are more likely to produce desired results. | Shifts decisions from “gut feeling” to using data from customer feedback, process metrics, and audit results, leading to more effective resource allocation. |

| 7. Relationship Management | For sustained success, an organisation manages its relationships with interested parties, such as suppliers and partners. | Recognizes that your supply chain’s quality affects your own. Fostering collaborative relationships with Malaysian suppliers enhances reliability and mutual growth. |

The Strategic Shift in 2015:

The 2015 revision of the standard placed significant new emphasis on two overarching themes that integrate these principles: Risk-Based Thinking and Organisational Context.

Risk-Based Thinking is the proactive consideration of risks and opportunities that could impact the QMS. It is about asking, “What could go wrong?” and “What could we do better?” before issues arise, embedding resilience into your operations.

Understanding Organisational Context requires you to analyse both internal factors (company culture, knowledge, performance) and external factors (market trends, regulatory changes in Malaysia, economic climate) that influence your strategic goals and how your QMS must operate.

Together, these principles and themes form a cohesive management model. Implementing a QMS based on ISO 9001:2015 is, therefore, an exercise in aligning your entire organisation with a proven framework for excellence, adaptability, and customer value creation.

The Malaysian Context: Requirements, Governance & Local Adoption

While ISO 9001 is an international standard, its implementation does not occur in a vacuum. For Malaysian organisations, successful adoption requires a clear understanding of the local regulatory framework, the accredited bodies involved, and how the standard is being applied across the nation’s diverse economy. This context transforms the standard from a generic guideline into a practical tool for Malaysian business excellence.

The Governing Framework: Jabatan Standard Malaysia (JSM)

In Malaysia, the apex authority for standards and quality is the Jabatan Standard Malaysia (JSM), operating under the Ministry of International Trade and Industry (MITI). JSM serves as the national standards body and is the Malaysian member of the International Organization for Standardization (ISO).

JSM’s key roles regarding ISO 9001 include:

Adopting the International Standard: JSM formally endorses and publishes the ISO 9001 standard within Malaysia, ensuring its alignment with the international version.

Accrediting Certification Bodies: JSM does not issue ISO 9001 certificates directly. Instead, it accredits independent certification bodies (CBs) to audit organisations against the standard. It is crucial to select a JSM-accredited CB to ensure your certification is nationally and internationally recognised.

Promoting Quality Culture: JSM actively promotes the benefits of standards like ISO 9001 to Malaysian industries through various programs and initiatives.

The Local Certification Ecosystem

The path to a recognised ISO 9001 certificate in Malaysia involves a clear chain of responsibility:

Your Organisation: Implements and maintains the QMS.

The Certification Body (CB): An independent, JSM-accredited organisation (e.g., SIRIM QAS, TÜV SÜD, Bureau Veritas) that conducts the official audits and issues the certificate.

JSM (The Accreditor): Provides oversight and accreditation to the CBs, ensuring their competence and integrity.

This structure guarantees that a certificate issued in Malaysia carries the same weight and credibility as one issued anywhere else in the world.

Adoption Across Malaysian Industries

ISO 9001 has seen widespread adoption across Malaysia’s key economic sectors, each with its own drivers:

Manufacturing & Export: Often the earliest adopters, using certification as a mandatory requirement to access global supply chains and export markets. Manufacturers can explore a detailed, sector-specific implementation roadmap in our guide to ISO 9001 for the Malaysian manufacturing industry.

Construction & Engineering: Employ the standard to manage complex projects, ensure material quality, and meet stringent client and regulatory specifications.

Services Sector: Rapidly growing in adoption, including IT companies, logistics firms, and healthcare providers, using it to standardise service delivery, enhance customer satisfaction, and gain a competitive edge in the domestic market.

Government Linked Companies (GLCs) & SMEs: Many GLCs require ISO 9001 from their vendors, driving adoption… For companies in the food and healthcare sectors, these requirements often extend to other certifications, creating a comprehensive compliance ecosystem. A strong QMS can significantly streamline the later adoption of standards like ISO 22000 for food safety management or Good Manufacturing Practice (GMP), particularly when seeking Halal certification in Malaysia, where documented control processes are crucial.

Key Consideration for Malaysian Businesses:

When implementing ISO 9001, it is vital to consider local business practices, cultural norms around documentation and process, and specific industry regulations (such as those from MOH, MOHR, or local authorities). A successful QMS is not a copy-paste of a foreign model; it is one that integrates seamlessly with how your Malaysian organisation operates while meeting the standard’s requirements.

The Step-by-Step Certification Journey in Malaysia

For any organization, the path to ISO 9001 certification is a structured project that demands careful planning and execution. Understanding this journey from the outset prevents costly missteps and sets the stage for long-term success. The following roadmap outlines the typical phases for a Malaysian organization, from initial commitment to ongoing compliance.

Phase 1: Preparation & Planning (Months 1-3)

This foundational phase is about building knowledge and a solid plan.

Management Commitment & Gap Analysis: Management Commitment & Gap Analysis: Secure top management buy-in. Conduct a gap analysis to compare current practices against ISO 9001 requirements. For a complete, step-by-step guide on how to perform this critical first step effectively, see our dedicated guide on conducting an ISO 9001 gap analysis for Malaysian SMEs. This highlights exactly what needs to be created or improved.

Project Planning & Awareness Training: Appoint a project team/management representative. Develop a realistic project plan with resources and timelines. Conduct ISO 9001 awareness training for staff to ensure organisation-wide understanding.

Documentation Development: Develop the required QMS documentation. This includes defining your quality policy, quality objectives, and necessary procedures as mandated by the standard. The key is to document what you do, not create burdensome paperwork.

Phase 2: Implementation & Internal Evaluation (Months 4-6)

This is the “doing” phase where the system becomes operational.

Full System Implementation: Roll out all new processes, documents, and controls across the organisation. This is often the most intensive period of change.

Internal Audit: Conduct internal audits to check whether the QMS conforms to planned arrangements and the standard’s requirements. Building internal competency for this critical activity is often achieved through a dedicated ISO 9001 Internal Auditor course. This self-check allows you to find and fix issues before the external audit and is a skill that translates to auditing other management systems, such as an Allergen Management Program in a food manufacturing context.

Management Review: Top management must formally review the QMS to ensure its continuing suitability, adequacy, effectiveness, and alignment with strategic direction.

Phase 3: The Certification Audit (Months 6-8)

This independent assessment is conducted by your chosen JSM-accredited Certification Body (CB). It is a two-stage process:

Stage 1 Audit (Documentation Review): Auditors review your QMS documentation to ensure it meets all requirements of the ISO 9001 standard and is ready for a full audit. They will also plan for Stage 2.

Stage 2 Audit (Certification Audit): Auditors visit your premises to evaluate the actual implementation and effectiveness of your QMS. They will interview staff, observe processes, and review records to verify that everything is working as documented.

Phase 4: Certification & Beyond

Certification Decision & Grant: If the Stage 2 audit is successful, the CB issues your official ISO 9001 certificate, valid for three years.

Surveillance Audits: To maintain certification, you will undergo annual surveillance audits (in Years 1 and 2). These are shorter audits to confirm the QMS is maintained and continues to perform.

Recertification Audit: Before your certificate expires at the end of Year 3, you will undergo a full recertification audit to renew your certificate for another three-year cycle.

Critical Success Factor for Malaysian Businesses:

A common pitfall is treating this as a “project for a certificate” that ends after the audit. True success comes from viewing the QMS as the operating system of your business—a living framework for daily management and continuous improvement, which leads to the tangible benefits discussed in the next section.

Benefits, Challenges & ROI for Malaysian Organizations

Adopting ISO 9001 is a strategic investment. Like any significant business initiative, it offers substantial returns but requires navigating certain challenges. A clear-eyed view of both the benefits and the hurdles enables Malaysian businesses to plan effectively, set realistic expectations, and maximize their return on investment (ROI).

Tangible & Intangible Benefits

The advantages of a well-implemented QMS extend across the entire organization, impacting both efficiency and market position.

| Benefit Category | Specific Advantages for Malaysian Organizations |

|---|---|

| Operational Excellence |

|

| Enhanced Market Position |

|

| Organizational Resilience |

|

Common Challenges & Realistic Considerations

Acknowledging potential obstacles is key to overcoming them. Common challenges include:

Perception as a “Paperwork Exercise”: The greatest risk is treating the QMS as a set of documents for auditors rather than a practical management tool. This undermines its value and leads to disengagement.

Resource Allocation: Initial implementation requires dedicated time and personnel. SMEs, in particular, may feel this strain.

Sustaining Momentum: Maintaining enthusiasm and rigorous compliance after certification can be difficult without ongoing management commitment.

Cultural Adaptation: Shifting from a “fire-fighting” mode to a preventive, process-oriented culture requires persistent leadership and communication.

Analysing the Return on Investment (ROI)

The ROI of ISO 9001 certification in Malaysia should be measured beyond the audit fees. A holistic calculation considers:

Costs: Direct costs (consultancy, training, certification body fees) and indirect costs (staff time, documentation systems).

Financial Returns: Measurable savings from reduced defects, lower operational costs, and increased sales from new contracts won due to certification.

Strategic Returns: Harder to quantify but critical: improved customer satisfaction, enhanced brand equity, reduced risk of non-conformities, and a more agile organization.

For many businesses, the strategic and financial returns compound over time, often outweighing the initial investment within the first 1-2 years post-certification. The key is to integrate the QMS with business goals, ensuring it drives real performance rather than being an isolated compliance activity.

Maintaining Compliance: Audit Cycles & The Culture of Continuous Improvement

Achieving ISO 9001 certification in Malaysia is a significant milestone, but it is not the final destination. The true value of a Quality Management System is realized through its ongoing use and evolution. This phase focuses on two interconnected objectives: maintaining compliance with certification requirements and fostering a culture of continuous improvement that drives business growth.

The Ongoing Audit Cycle: Surveillance and Recertification

Your relationship with your Certification Body (CB) continues on a defined cycle to ensure your QMS remains effective and conforms to the standard.

Surveillance Audits (Annual – Years 1 & 2): These are mandatory audits conducted annually after certification. They are less extensive than the initial certification audit but are crucial checks on the health of your QMS. Auditors will typically:

Review the effectiveness of your QMS in key areas.

Check that internal audits and management reviews are being conducted.

Verify that corrective actions from previous audits have been addressed.

Ensure the system continues to meet the standard’s requirements.

Recertification Audit (Year 3): Before your three-year certificate expires, you will undergo a full recertification audit. This audit is comprehensive, similar to the initial Stage 2 audit, to verify the continued effectiveness and relevance of your entire QMS for a new three-year term.

💡Pro Tip for Malaysian Businesses: Treat surveillance audits as value-adding health checks, not as burdensome inspections. A good auditor can provide external, expert insights that help you improve.

Embedding Continuous Improvement (Kaizen)

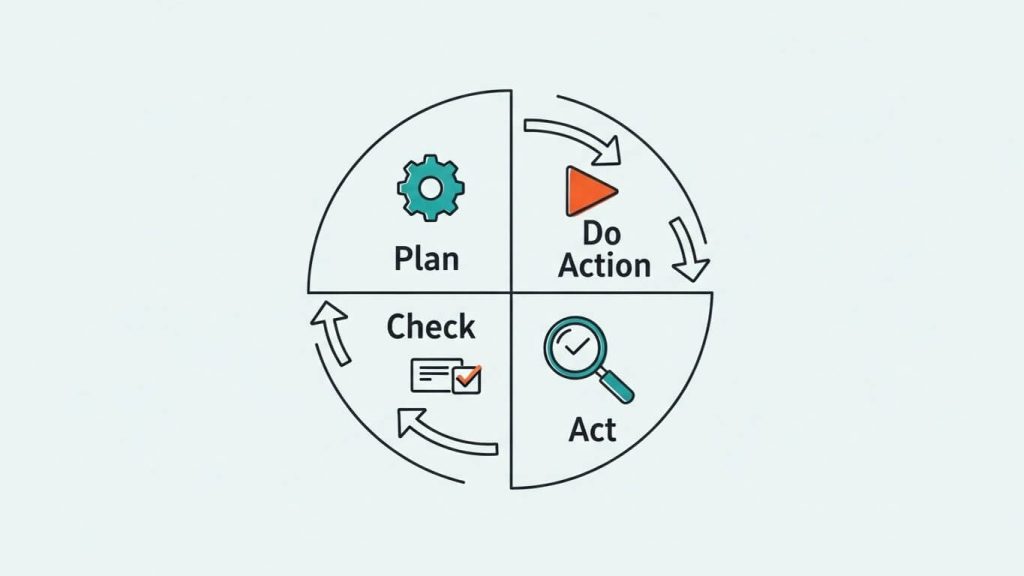

Beyond compliance, the core purpose of your QMS is continual improvement. The standard provides a powerful, cyclical model for this: the Plan-Do-Check-Act (PDCA) cycle.

Plan: Establish objectives and processes necessary to deliver results in accordance with customer requirements and organizational policies.

Do: Implement the processes as planned.

Check: Monitor and measure processes against policy, objectives, and requirements, and report the results.

Act: Take actions to continually improve process performance.

For Malaysian organizations, this means systematically using outputs from your internal audits, management reviews, customer feedback, and performance data to identify opportunities. An improvement can be as simple as streamlining a form or as significant as overhauling a production process.

The Role of Management Review

The management review is not a one-time event for certification. It is a periodic, formal meeting where top management assesses the QMS’s continuing suitability, adequacy, effectiveness, and alignment with strategic direction. Key inputs include:

Audit results (internal and external).

Customer feedback and satisfaction data.

Process performance and product conformity.

Status of corrective actions.

Changes in organizational context (e.g., new Malaysian regulations, market conditions).

This review is the strategic engine that translates operational data into decisions for resource allocation and improvement initiatives, ensuring the QMS remains a dynamic business tool.

Conclusion of the Journey:

A successful ISO 9001 QMS is a living system. It moves an organization from seeking a “sijil” (certificate) to mastering a “sistem” (system)—from a static achievement to a dynamic capability for quality, resilience, and growth in the Malaysian marketplace.

Essential Resources & Next Steps for Your Organization

By reaching this point, you have gained a comprehensive understanding of ISO 9001 in Malaysia—from its strategic value and core principles to the practicalities of certification and long-term maintenance. This knowledge empowers you to make informed decisions. To support your journey, we have compiled essential resources and neutral guidance for the path ahead.

Official References & Authoritative Links

For the most accurate and up-to-date information, always refer to the primary sources:

International Organization for Standardization (ISO): The official ISO 9001:2015 page provides the full standard for purchase.

Jabatan Standard Malaysia (JSM): The national standards body’s website offers crucial local context, news, and directories. Visit their Standards Malaysia portal for information.

Accreditation Directory: To verify a Certification Body, consult the JSM Directory of Accredited Bodies. This ensures you select a properly accredited partner for your certification audit.

A Neutral Guide to Selecting Training & Support

Implementing ISO 9001 is a team effort. Many organizations benefit from external training or guidance. When evaluating potential partners, consider these key criteria to find the right fit for your Malaysian business:

Trainer Credentials & Experience: Look for lead auditors or consultants with extensive, real-world implementation experience, not just theoretical knowledge. Their industry background should be relevant to your sector.

Alignment with Your Journey: The training curriculum should clearly map to the different phases of the certification journey—from awareness and gap analysis to internal auditor training and preparation for external audits.

Practicality & Local Context: The training should provide practical tools, templates, and examples relevant to the Malaysian business and regulatory environment.

Post-Training Value: Consider what support is offered after the course, such as access to resources, clarification support, or follow-up consultancy, to aid your implementation.

Your Informed Next Step with Al-Barakah

At Al-Barakah, we believe knowledge is the foundation of quality. This guide was created to provide unbiased, comprehensive education because an informed client is a successful client.

Our ISO 9001 training programs are designed based on the very principles and journey outlined in this guide. We focus on building your team’s internal competency, ensuring your QMS is a practical, value-adding asset—not just a compliance document.

Continue Your Exploration:

Deepen Your Knowledge: Browse our [Insights Blog] for detailed articles on specific topics like risk-based thinking, internal auditing, and documentation.

Explore Our Learning Philosophy: Understand how our trainer expertise, practical course modules, and supportive approach align with your needs. [Discover Our Training Programs].